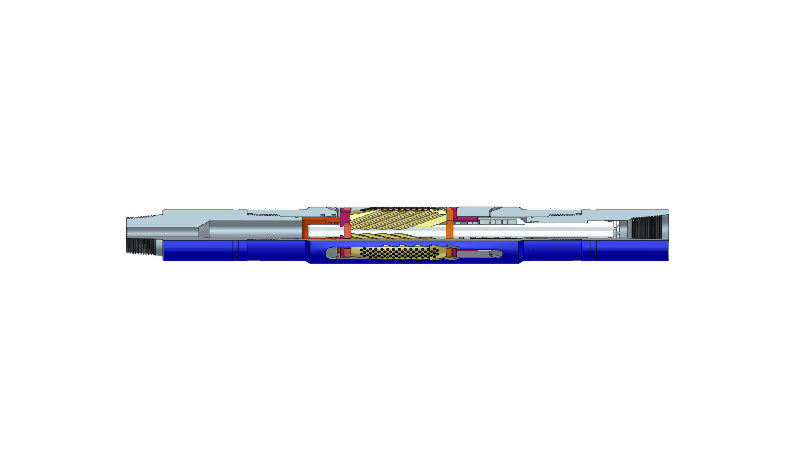

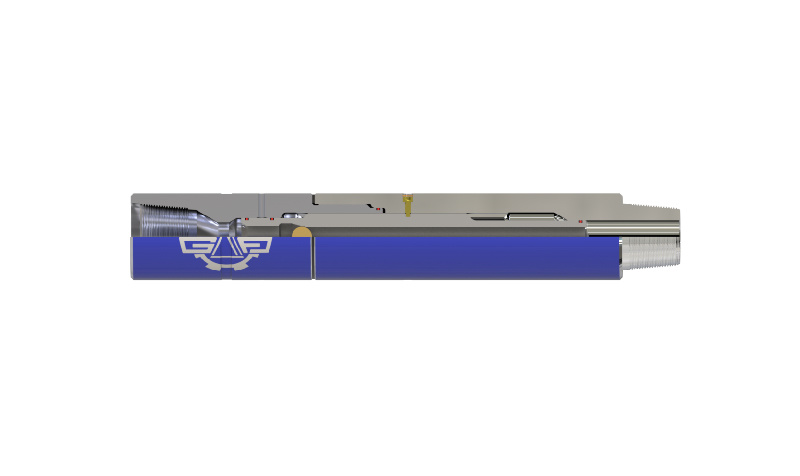

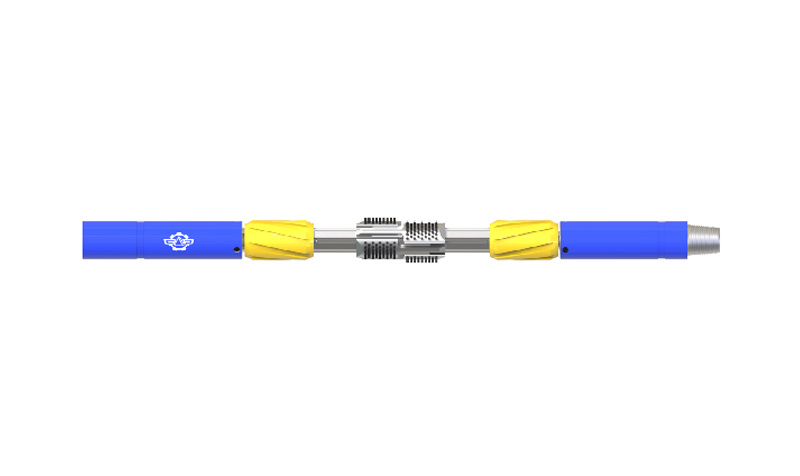

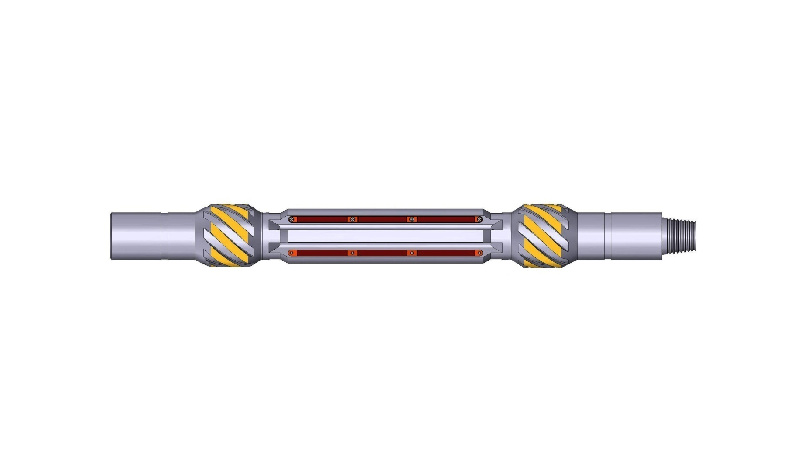

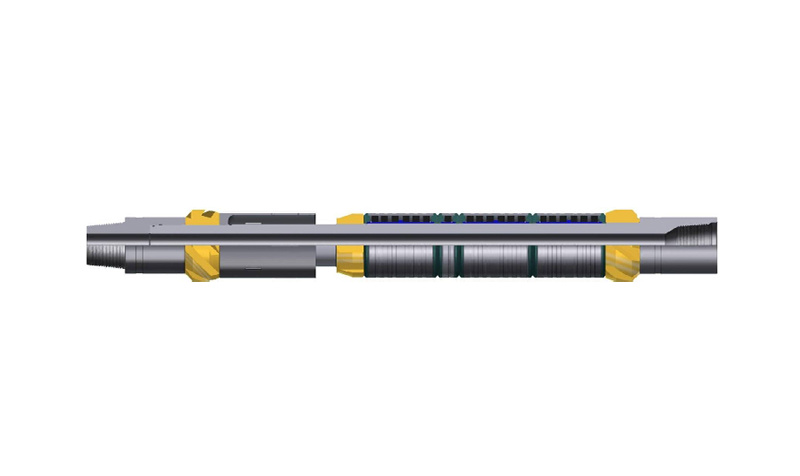

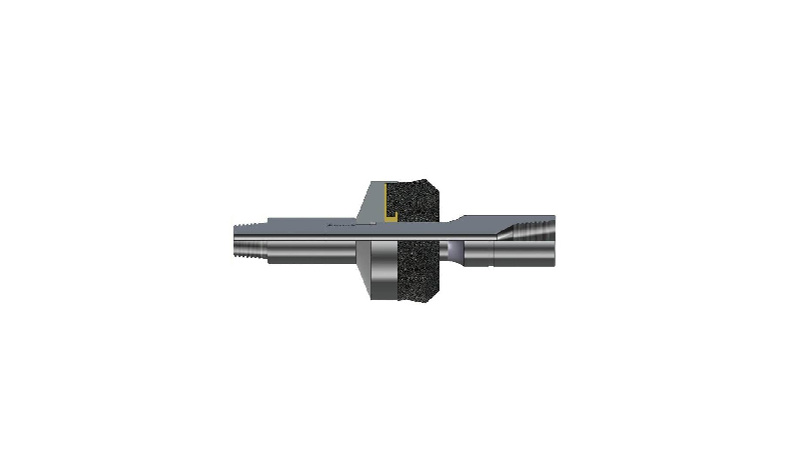

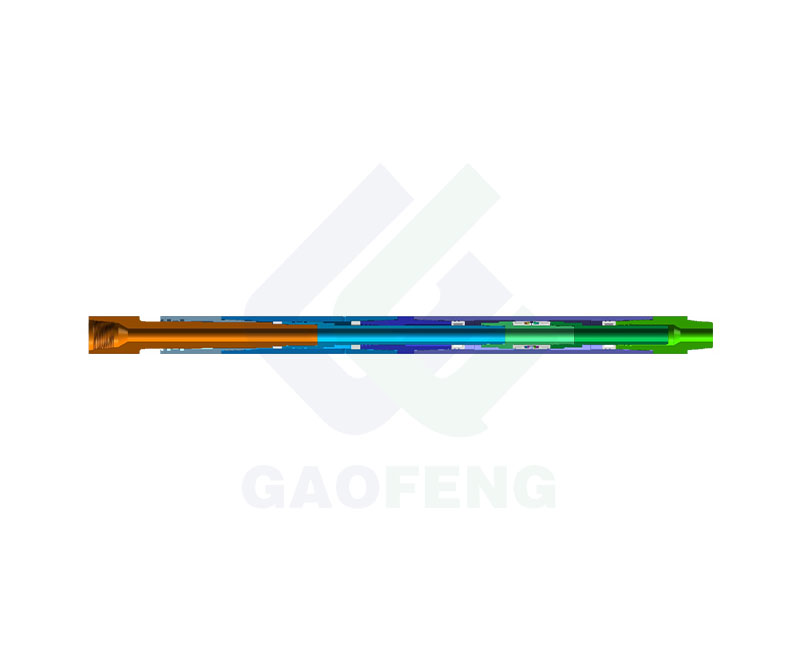

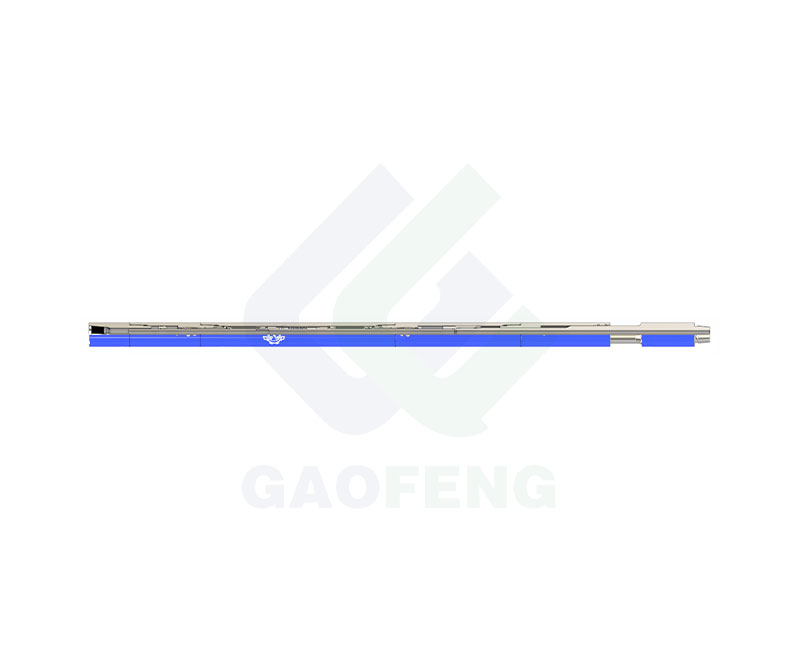

Non-magnetic Drill Collars

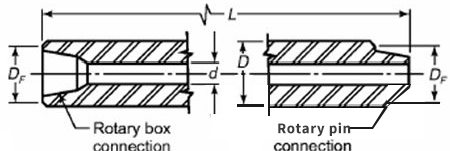

Non-magnetic Drill CollarsNon-magnetic Drill Collars using self-developed low-carbon stainless steel as API specification and implementation of SY / T5144 standard, which can be cold thread rolling, machine special double shoulder screw thread and by other specifications.NMDC DIMENSIONDrill Collar ModelOD DID dOALL mmShoulder ChamferDF mmBending Strength RatiomminmminNC23-3179.43 1/831.81 1/4915076.22.57:1NC26-3588.93 1/238.11 1/2915082.92.42:1NC31-41104.84 1/850.829150 or 9450100.42.43:1NC35-47120.74 3/450.829150 or 9450114.72.58:1NC38-50127.0557.22 1/49150 or 9450121.02.38:1NC44-60152.4657.22 1/49150 or 9450144.52.49:1NC44-60152.4671.42 13/169150 or 9450144.52.84:1NC44-62158.86 1/457.22 1/49150 or 9450149.22.91:1NC46-62158.86 1/471.42 13/169150 or 9450150.02.63:1NC46-65165.16 1/257.22 1/49150 or 9450154.82.76:1NC46-65165.16 1/271.42 13/169150 or 9450154.83.05:1NC46-67171.46 3/457.22 1/49150 or 9450159.53.18:1NC50-67171.46 3/471.42 13/169150 or 9450159.52.37:1NC50-70177.8757.22 1/49150 or 9450164.72.54:1NC50-70177.8771.42 13/169150 or 9450164.72.73:1NC50-72184.27 1/471.42 13/169150 or 9450169.53.12:1NC56-77196.87 3/471.42 13/169150 or 9450185.32.70:1NC56-80203.2871.42 13/169150 or 9450190.13.02:16 5/8REG209.68 1/471.42 13/169150 or 9450195.72.93:1NC61-90228.6971.42 13/169150 or 9450212.73.17:17 5/8REG241.39 1/276.239150 or 9450223.82.81:1NC70-97247.69 3/476.239150 or 9450232.62.57:1NC70-100254.01076.239150 or 9450237.3281:18 5/8REG279.41176.239150 or 9450266.72.84:1 Tolerance for NMDC Major DimensionOD RANGEOD DID dOAL LShoulder ChamferDFmmin≤88.9≤3 1/2+1.2 0+1.6 0+152.4±0.4>88.9~114.3>3 1/2~4 1/2+1.6 0>114.3~139.7>4 1/2~5 1/2+2.0 0>139.7~165.1>5 1/2~6 1/2+3.2 0>165.1~215.9>6 1/2~8 1/2+4.0 0>215.9~241.3>8 1/2~9 1/2+4.8 0>241.3>9 1/2+6.4 0 NMDC Mechanical PerformancesOD RANGEYIELD STRENGTH σ0.2 MPaTENSILE STRENGTH σb MPaELONGATION δ4 %mmin79.4~171.43 1/8~6 3/4≥758≥827≥18177.8~279.47~11≥689≥758≥20Magnetic Performance(Magnetic Field=1×105/4πA/m)1.relative magnetic permeability Ur<1.0102.magnetic field gradient:ΔB≤0.05μT

Category:

Detailed introduction

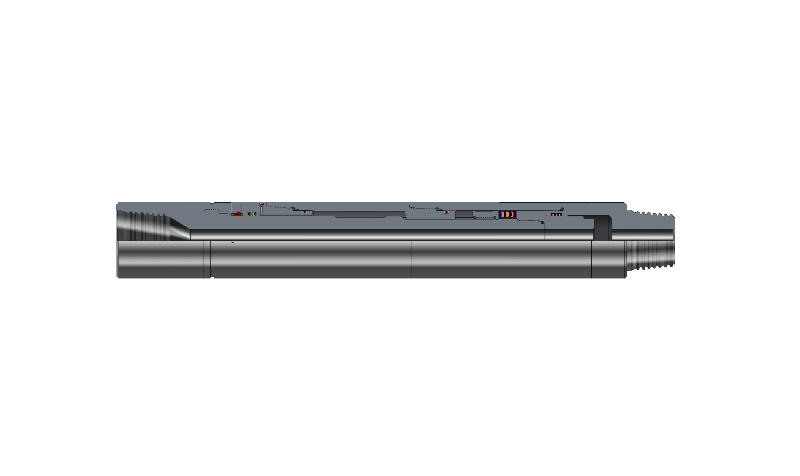

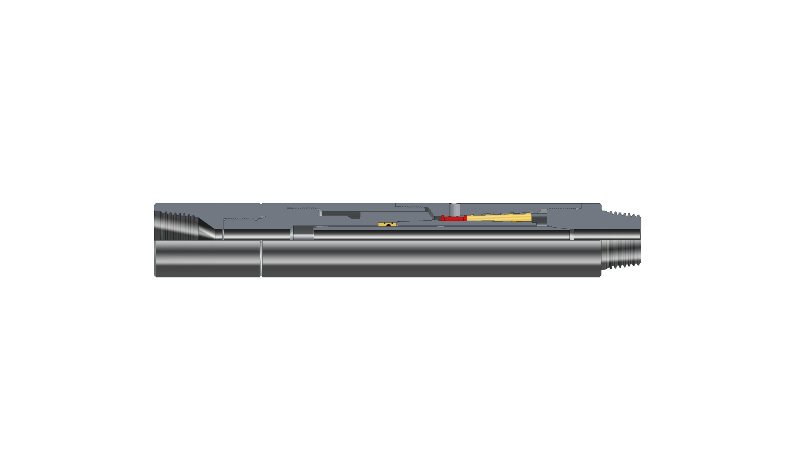

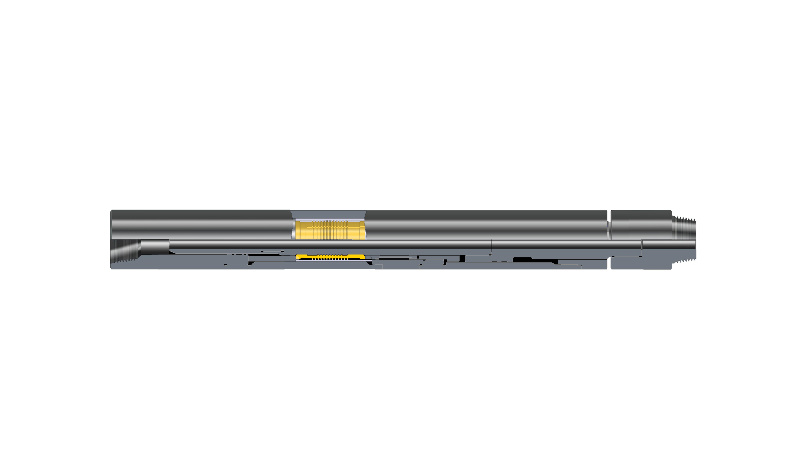

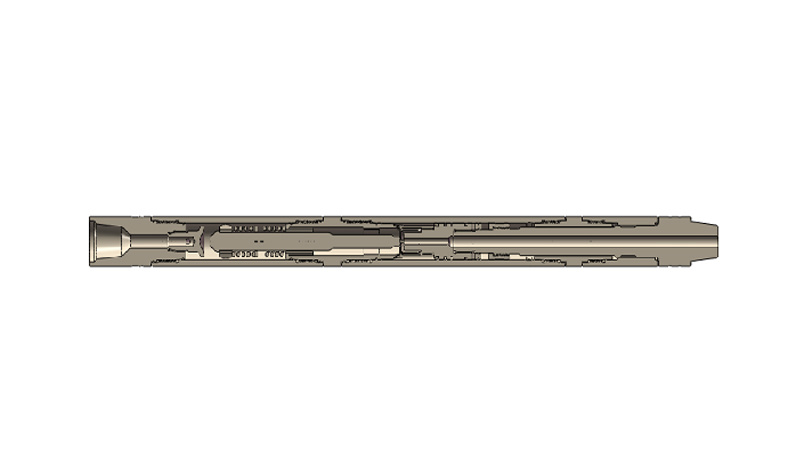

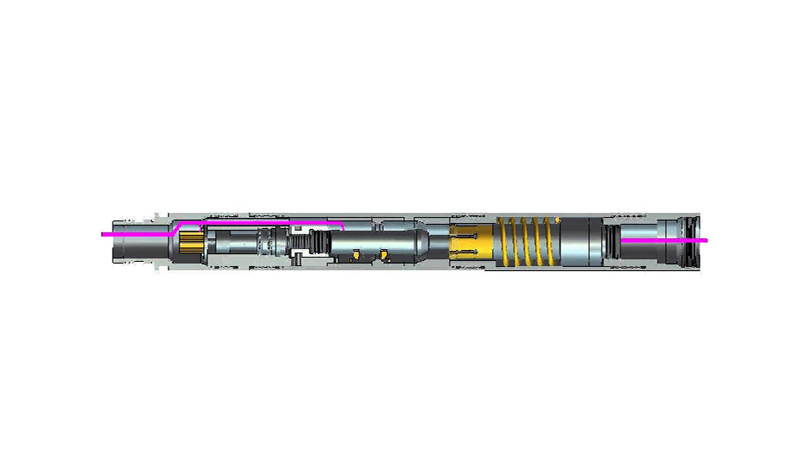

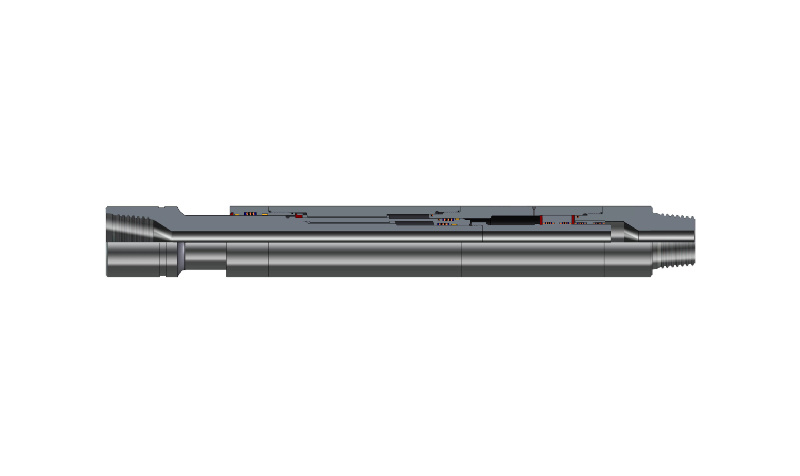

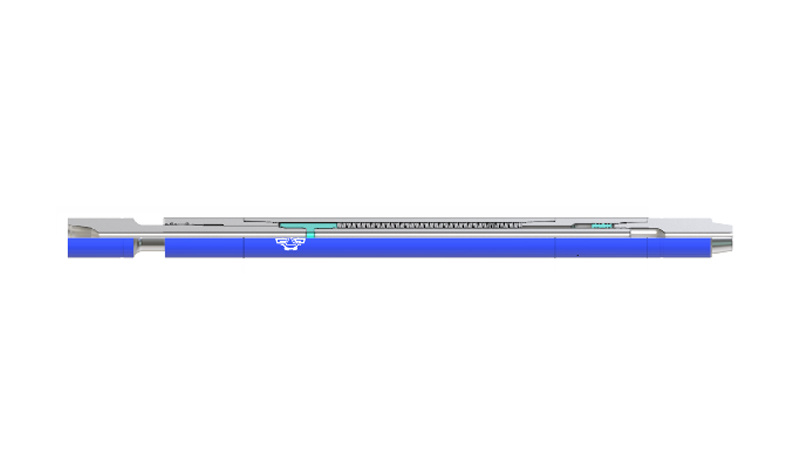

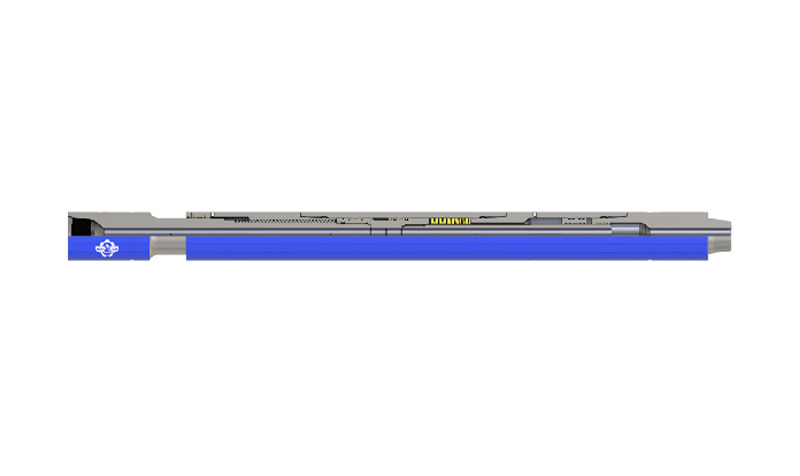

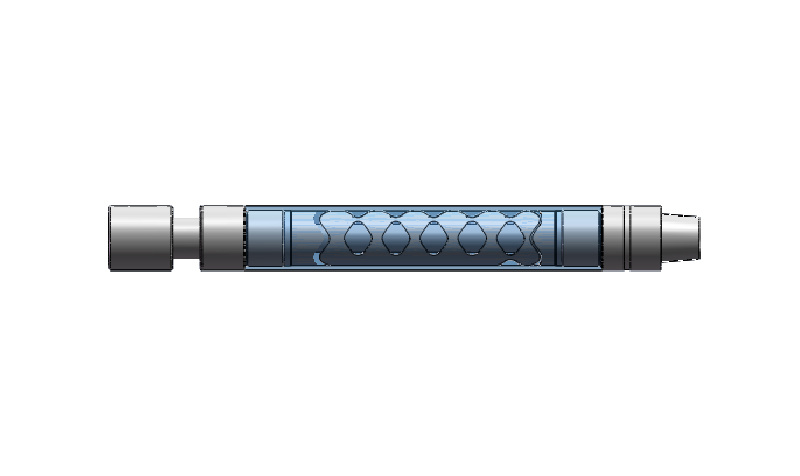

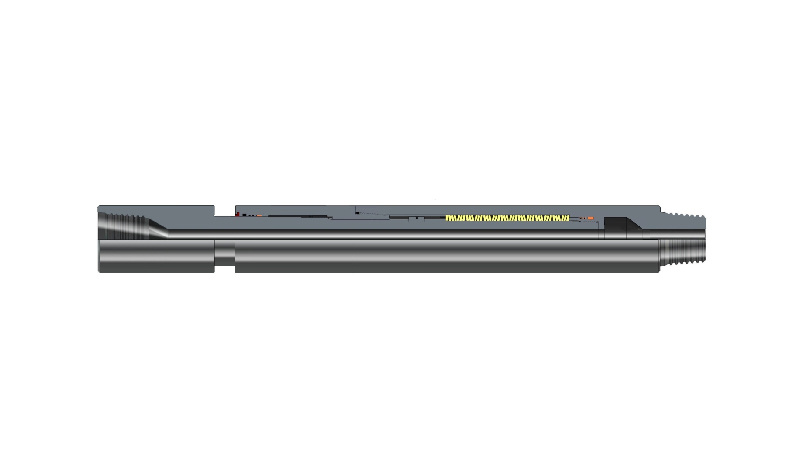

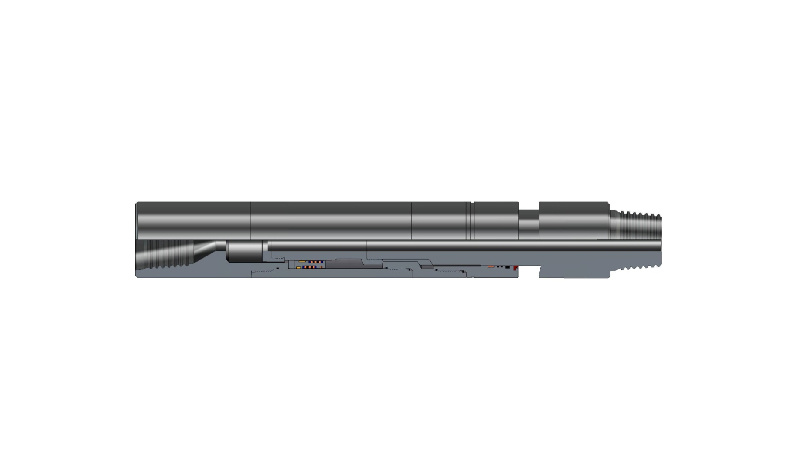

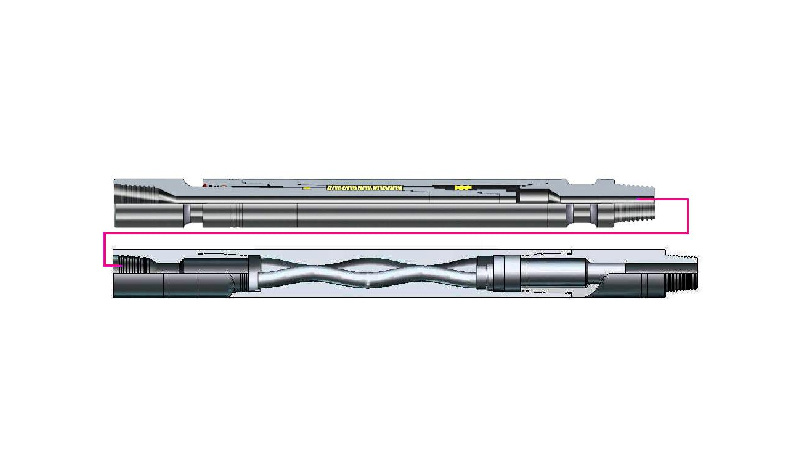

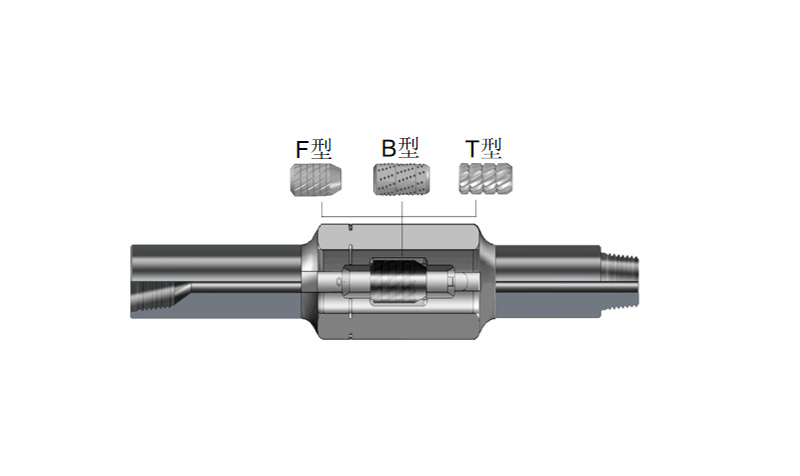

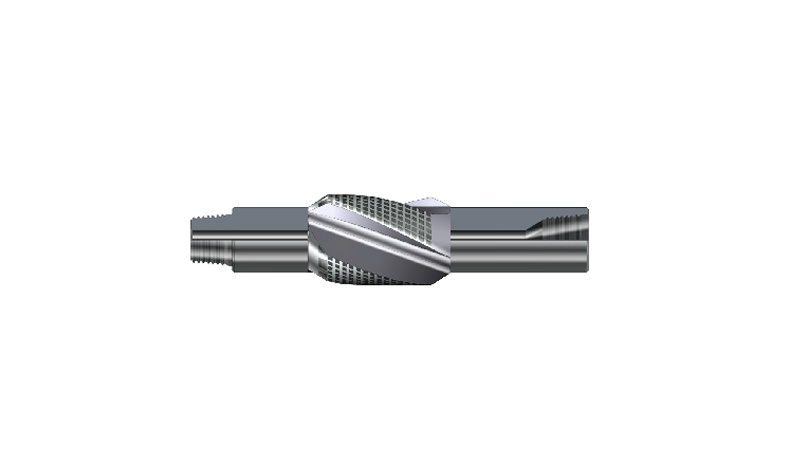

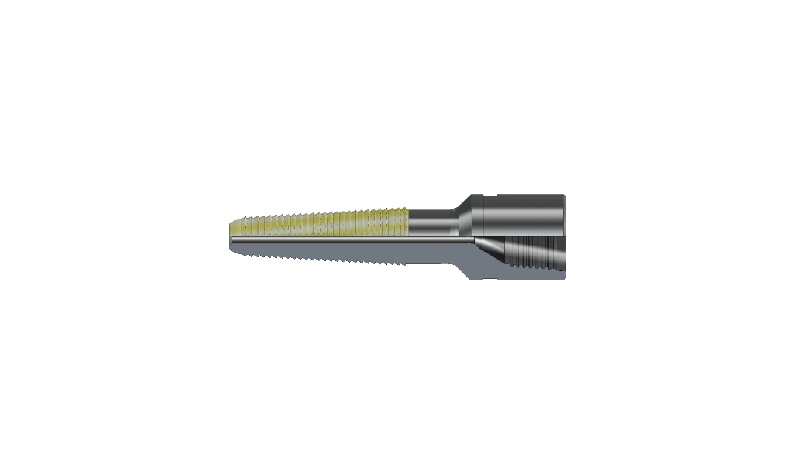

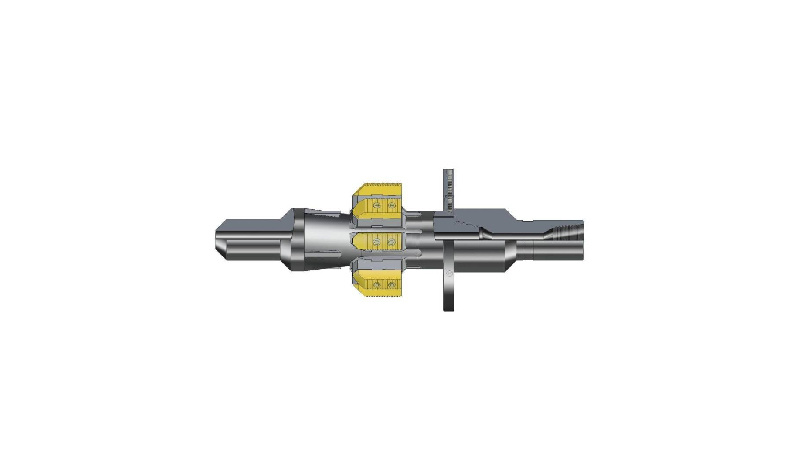

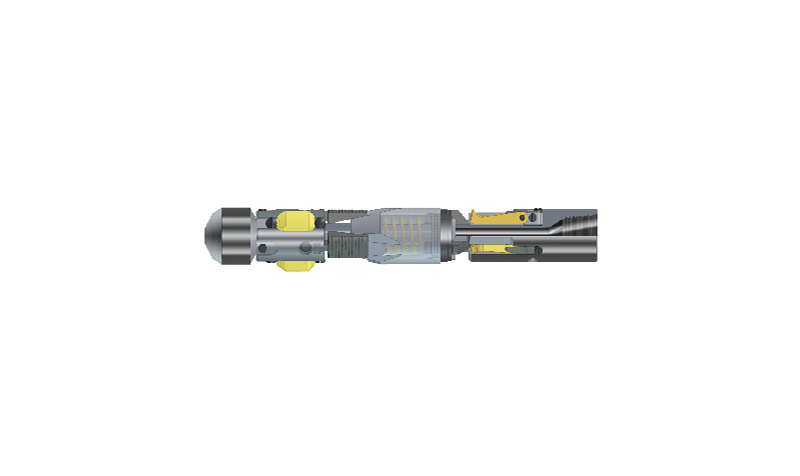

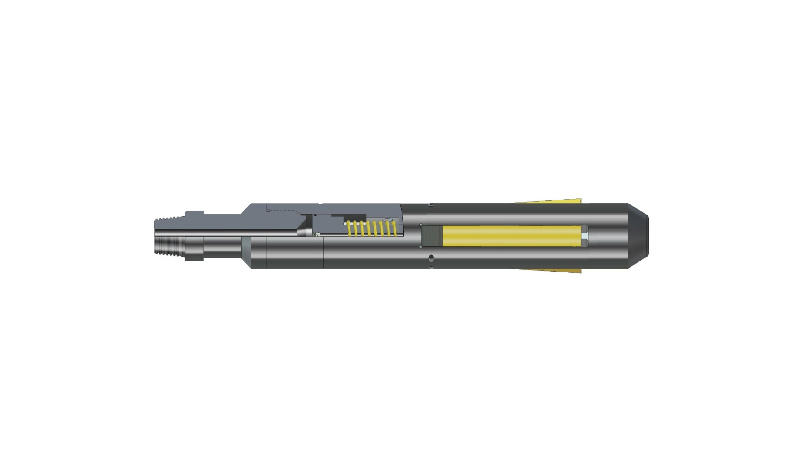

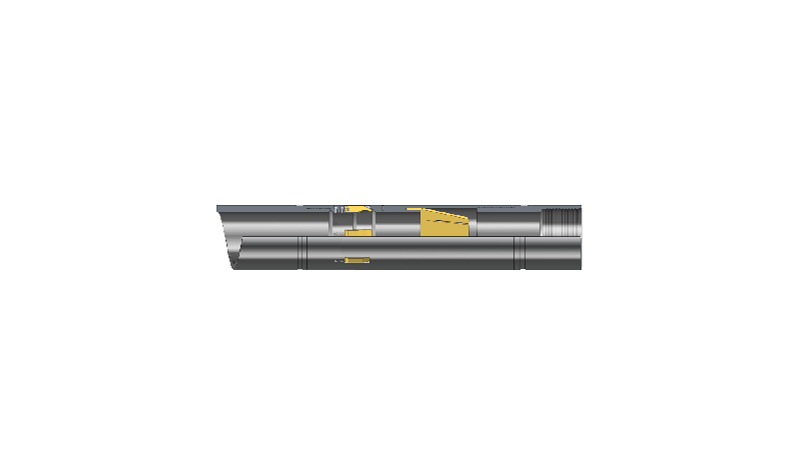

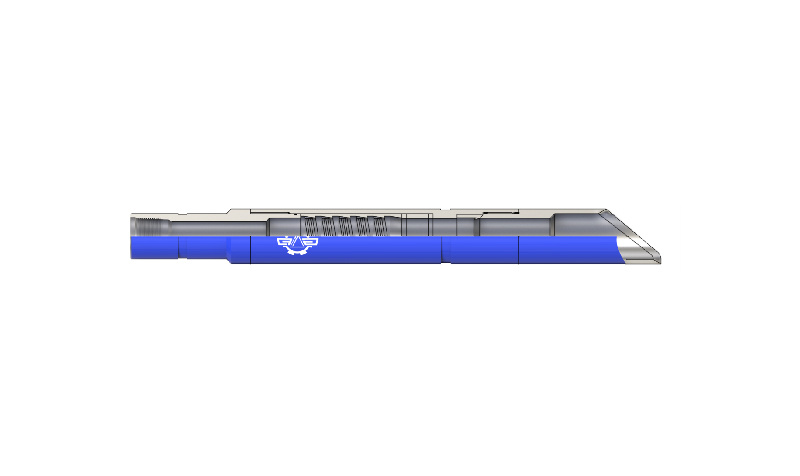

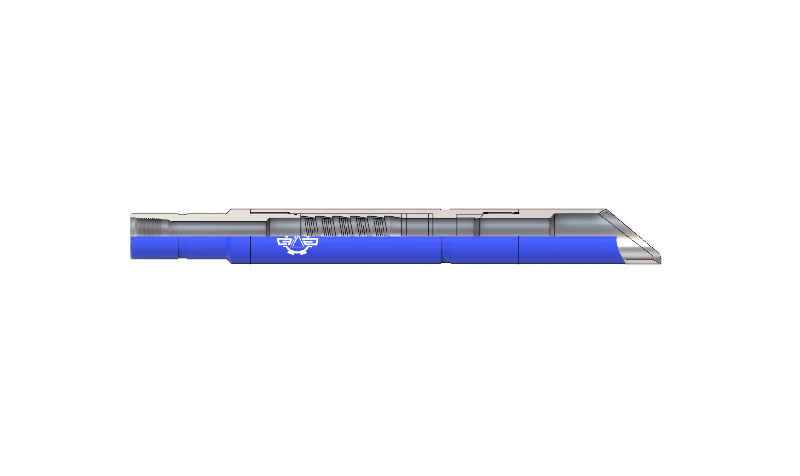

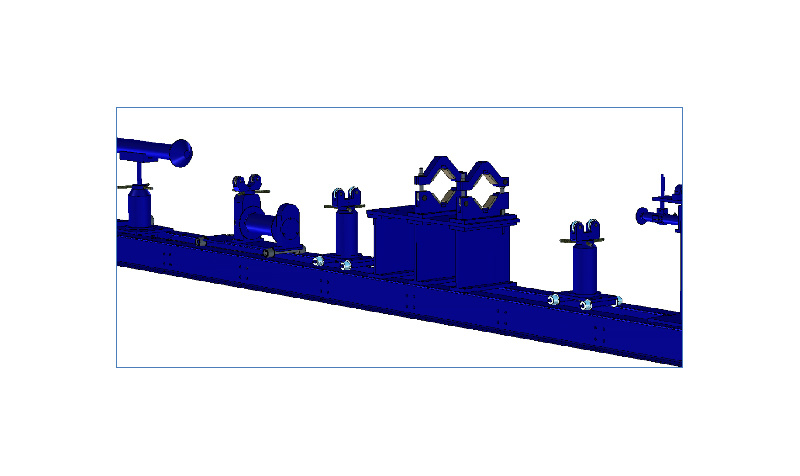

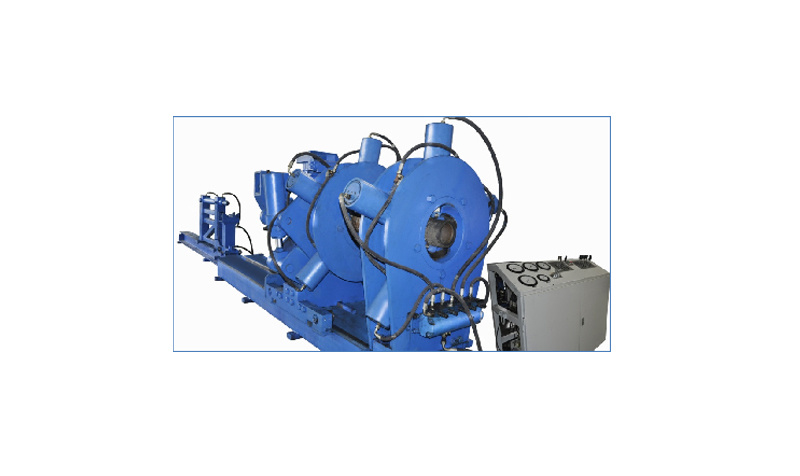

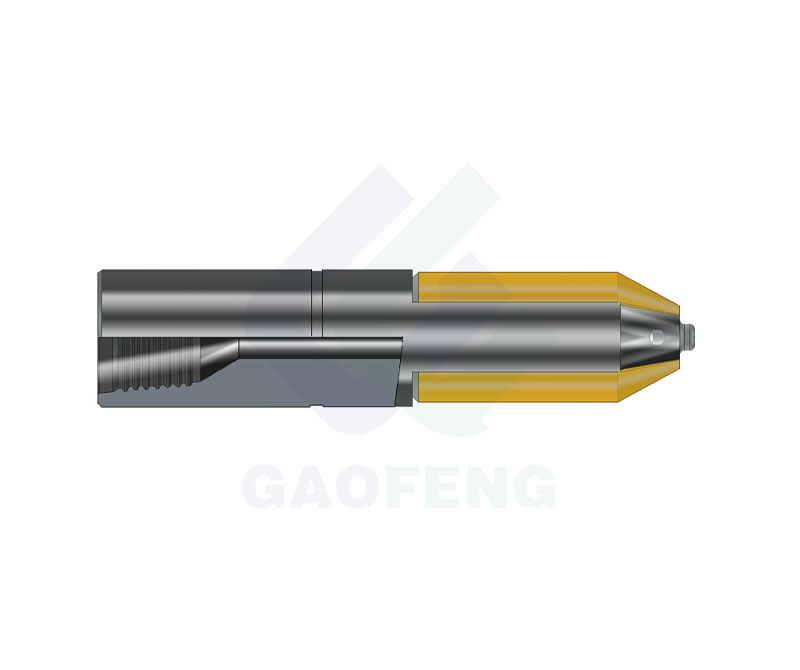

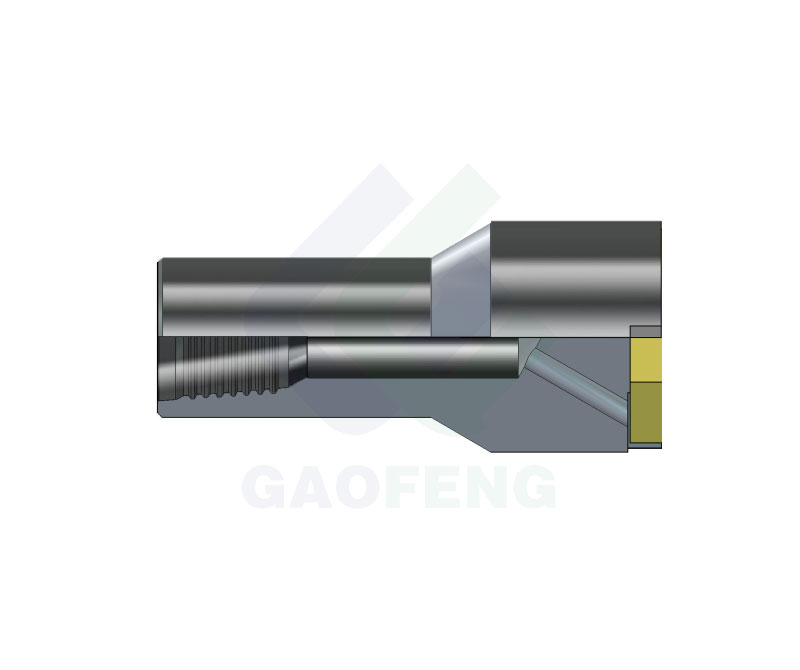

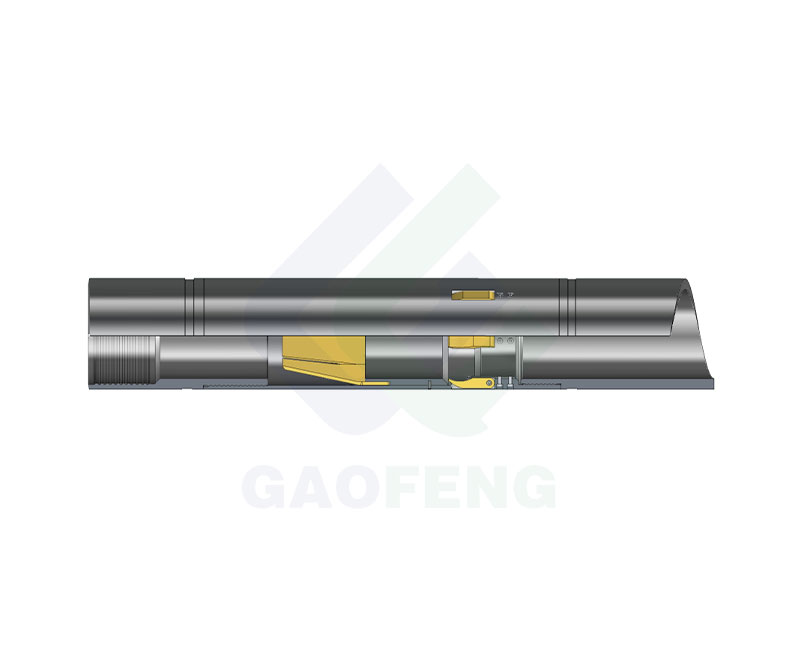

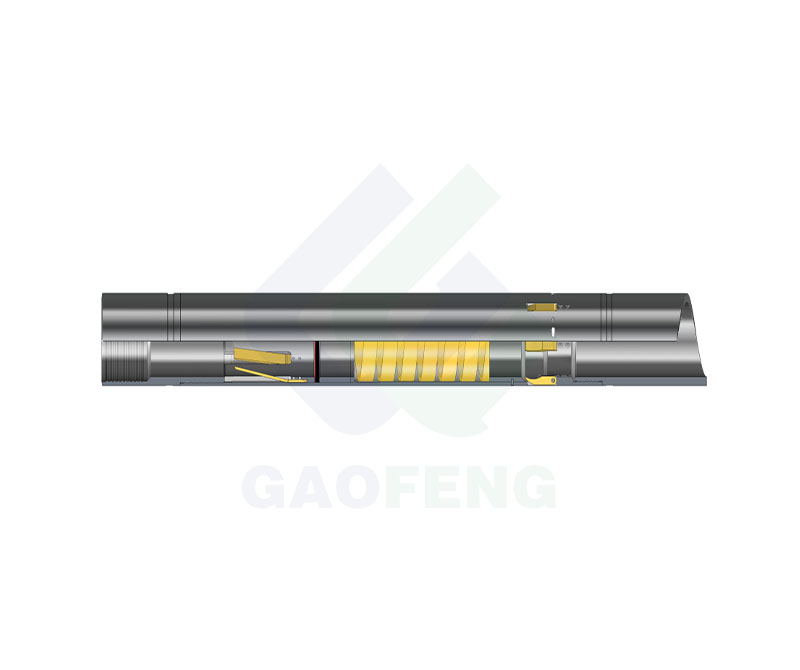

Non-magnetic Drill Collars using self-developed low-carbon stainless steel as API specification and implementation of SY / T5144 standard, which can be cold thread rolling, machine special double shoulder screw thread and by other specifications.

NMDC DIMENSION

| Drill Collar Model | OD D | ID d |

OAL L mm |

Shoulder Chamfer DF mm |

Bending Strength Ratio | ||

| mm | in | mm | in | ||||

| NC23-31 | 79.4 | 3 1/8 | 31.8 | 1 1/4 | 9150 | 76.2 | 2.57:1 |

| NC26-35 | 88.9 | 3 1/2 | 38.1 | 1 1/2 | 9150 | 82.9 | 2.42:1 |

| NC31-41 | 104.8 | 4 1/8 | 50.8 | 2 | 9150 or 9450 | 100.4 | 2.43:1 |

| NC35-47 | 120.7 | 4 3/4 | 50.8 | 2 | 9150 or 9450 | 114.7 | 2.58:1 |

| NC38-50 | 127.0 | 5 | 57.2 | 2 1/4 | 9150 or 9450 | 121.0 | 2.38:1 |

| NC44-60 | 152.4 | 6 | 57.2 | 2 1/4 | 9150 or 9450 | 144.5 | 2.49:1 |

| NC44-60 | 152.4 | 6 | 71.4 | 2 13/16 | 9150 or 9450 | 144.5 | 2.84:1 |

| NC44-62 | 158.8 | 6 1/4 | 57.2 | 2 1/4 | 9150 or 9450 | 149.2 | 2.91:1 |

| NC46-62 | 158.8 | 6 1/4 | 71.4 | 2 13/16 | 9150 or 9450 | 150.0 | 2.63:1 |

| NC46-65 | 165.1 | 6 1/2 | 57.2 | 2 1/4 | 9150 or 9450 | 154.8 | 2.76:1 |

| NC46-65 | 165.1 | 6 1/2 | 71.4 | 2 13/16 | 9150 or 9450 | 154.8 | 3.05:1 |

| NC46-67 | 171.4 | 6 3/4 | 57.2 | 2 1/4 | 9150 or 9450 | 159.5 | 3.18:1 |

| NC50-67 | 171.4 | 6 3/4 | 71.4 | 2 13/16 | 9150 or 9450 | 159.5 | 2.37:1 |

| NC50-70 | 177.8 | 7 | 57.2 | 2 1/4 | 9150 or 9450 | 164.7 | 2.54:1 |

| NC50-70 | 177.8 | 7 | 71.4 | 2 13/16 | 9150 or 9450 | 164.7 | 2.73:1 |

| NC50-72 | 184.2 | 7 1/4 | 71.4 | 2 13/16 | 9150 or 9450 | 169.5 | 3.12:1 |

| NC56-77 | 196.8 | 7 3/4 | 71.4 | 2 13/16 | 9150 or 9450 | 185.3 | 2.70:1 |

| NC56-80 | 203.2 | 8 | 71.4 | 2 13/16 | 9150 or 9450 | 190.1 | 3.02:1 |

| 6 5/8REG | 209.6 | 8 1/4 | 71.4 | 2 13/16 | 9150 or 9450 | 195.7 | 2.93:1 |

| NC61-90 | 228.6 | 9 | 71.4 | 2 13/16 | 9150 or 9450 | 212.7 | 3.17:1 |

| 7 5/8REG | 241.3 | 9 1/2 | 76.2 | 3 | 9150 or 9450 | 223.8 | 2.81:1 |

| NC70-97 | 247.6 | 9 3/4 | 76.2 | 3 | 9150 or 9450 | 232.6 | 2.57:1 |

| NC70-100 | 254.0 | 10 | 76.2 | 3 | 9150 or 9450 | 237.3 | 281:1 |

| 8 5/8REG | 279.4 | 11 | 76.2 | 3 | 9150 or 9450 | 266.7 | 2.84:1 |

Tolerance for NMDC Major Dimension

| OD RANGE | OD D | ID d | OAL L |

Shoulder Chamfer DF |

|

| mm | in | ||||

| ≤88.9 | ≤3 1/2 | +1.2 0 | +1.6 0 | +152.4 | ±0.4 |

| >88.9~114.3 | >3 1/2~4 1/2 | +1.6 0 | |||

| >114.3~139.7 | >4 1/2~5 1/2 | +2.0 0 | |||

| >139.7~165.1 | >5 1/2~6 1/2 | +3.2 0 | |||

| >165.1~215.9 | >6 1/2~8 1/2 | +4.0 0 | |||

| >215.9~241.3 | >8 1/2~9 1/2 | +4.8 0 | |||

| >241.3 | >9 1/2 | +6.4 0 | |||

NMDC Mechanical Performances

| OD RANGE | YIELD STRENGTH σ0.2 MPa | TENSILE STRENGTH σb MPa | ELONGATION δ4 % | |

| mm | in | |||

| 79.4~171.4 | 3 1/8~6 3/4 | ≥758 | ≥827 | ≥18 |

| 177.8~279.4 | 7~11 | ≥689 | ≥758 | ≥20 |

Magnetic Performance(Magnetic Field=1×105/4πA/m)

1.relative magnetic permeability Ur<1.010

2.magnetic field gradient:ΔB≤0.05μT

Key words:

Gaofeng petroleum machinery and equipment, oil and gas drilling and production downhole tools

Previous

Previous

Contact Us

Add:No.2, Changling South Road, Guanshanhu Distict, Guiyang City, Guizhou Province

Business Cooperation

WeChat Sweep

Learn more about gaofeng information

Related Products

Fill out the form for more product details!